As we discussed in our previous article, fermentation is a crucial and indispensable stage in the transition from coffee cherry to green bean.

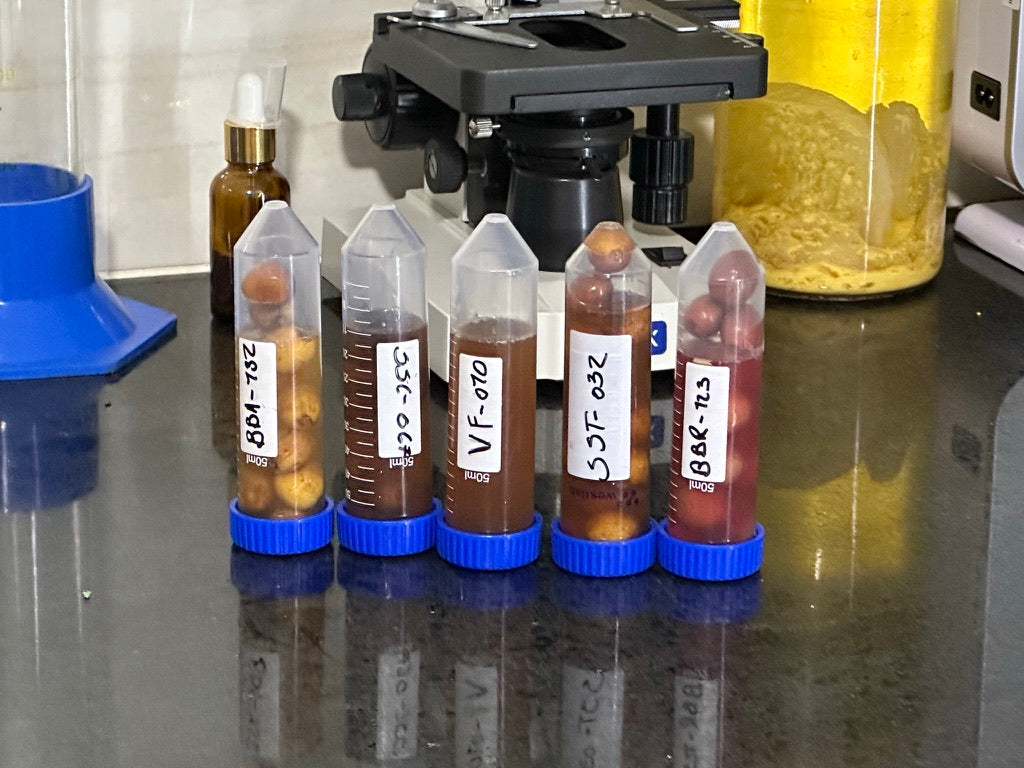

In recent years, producers have been experimenting with new methods of controlled fermentation. They are adding fermentation steps, using external yeasts, mushrooms, juice from other coffee cherries, dried fruit, and extended fermentation. These techniques not only bring out the best in each coffee cherry, but also create new tasting profiles, while increasing the selling price.

In this article, we'll explore the most popular experiments today, their impact on the final cup, and the associated costs and risks for producers.

Pre-fermentation

After picking, the cherries are stored undamaged for a few hours.

This pre-fermentation initiates an internal fermentation process similar to that of natural coffees. If properly controlled-ideally between 24 and 48 hours, depending on climate and thickness of the cherry layer-it can add sweetness and more intense fruit notes to the cup [1].